fabric winders and laminator

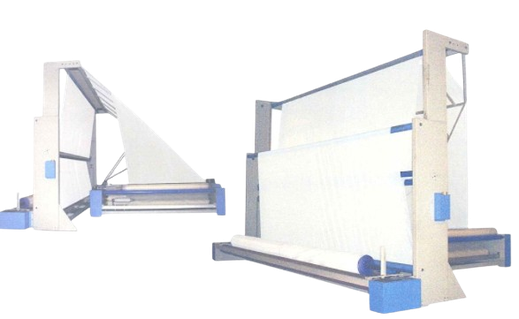

ALBALLOM

Machine the roll and fold cloth.

- Due to its special fabric folding system, this machine is desgned to roll widthways and lengthways.

- It can be supplied with a cradle of rollers for small-diameter fabric pieces or with pneumatic unrolling arms for large-diameter fabric rolls.

TECHNICAL FIGURES:

- Adjustable cloth rolls tightening system.

- Adjustable rolling speed (0-35metres/minute).

- Pneumatic fabric rod aligning system and driven by photocells.

- Metre counter with relay output.

Rolling machine to roll fabric from a roll to another, with the following figures:

- Electronic speed adjuster, from 0 to 30 m.

- Electronic counter.

- Pre-selector of measurements.

- Start, stop and safety stop push buttons.

- Rotation direction selector.

- Fabric capacity: rolls of 350mm diameter X 3.200mm long.

Different measurements can be produced according to the costumer requirements.

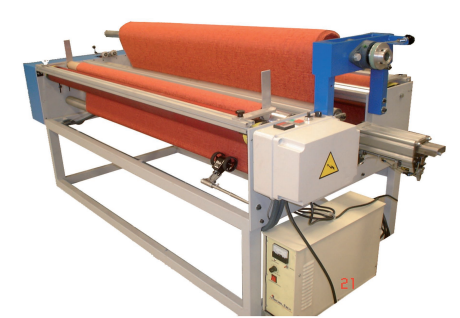

MINIRROLL

INSPECTION MINIROLL

Roll to roll fabric winding machine with:

- Encoder driven counter and pre-selection of measures.

- With inspection table.

- Electronic speed variator driven by potentiometer from 0 to 34 mtrs.

- Start and stop push button.

- Direction of rotation selector (forward-backward).

- Roll capacity: In cradle (450 mm diameter) and in winding (260 mm wide).

- Fabric capacity 1,600 mm wide.

- Can be manufactured in different lengths upon request.

Machine to roll any kind of fabric from roll to roll with automatic cutting of the fabric, pre selection of measures and metres counter.

With several useful fabric width capacities until 1.600mm and rolls capacity in cot of 450mm diametre and 260mm diametre in rolling.

The unrolling of the fabric is fed by rolling cot supplies the rolling in a continuous and regular way. It also includes a quick manual extraction system of the fabric to be rolled.

The two lateral limits which are mounted in the machine assure the perfect rolling of the fabric.

Automatic cutting system with circular blade, this machine is equipped with metres counter driven by encoder which allows us to pre selection the number of metres to be rolled, cut very easily, stop the machine at the selecttionned measure and make the cutting. For the accomplishment of the cutting the machine has got a fabric pressing device with safety system, a gear teeth lineal guide that ensures a perfect cutting and a circular blade of 200mm diametre.

It is also eqquiped with speed variator driven by power supply that allows us to adjust the speed from 0 to 34 metres/minute.

Control board with push buttons of starting, stopping and first cutting.

Sense of rotation forwards or backwards, etc.

This machine can be manufactured in different measures depending on the customers requirements.

MINIRROLL WITH BLADE

MINIRROLL ULTRASO

Machine for rolling fabric from one roll to 2 rolls. From a fan-folder rollof fabric, this machine produces 2 ultrasonic cut rolls.

TECHNICAL CHARACTERISTICS:

- Electronic counter driven by encoder with pre selection of measures.

- Electronic speed adjuster, driven by outside power supply from 0 to 20 metres/minute.

- Push button of starting.

- Push button for security Z.

- Sense of turning selector (forwards-backwards, only in the roll to be cut).

- Fabric capacity: In cot: 500mm diameter. In rolling 300mm diameter.

- Fabric capacity rolls: 1.700 mm length.

- Safety system following CE rules.

DIMENSIONS OF THE MACHINE:

- 1.000mm high.

- 1.000mm wide.

- 2.200mm length aprox.

Rolling machine to roll fabric from a roll to another, with the following figures:

- Electronic speed adjuster, from 0 to 30 m.

- Electronic counter.

- Pre-selector of measurements.

- Start, stop and safety stop push buttons.

- Rotation direction selector.

- Fabric capacity: rolls of 350mm diameter X 3.200mm long.

- Inspection panel for fabric faults.

- Fabric breaker and opener system for maximum fabric width.

- Alignment system.

- Perfect winding pressure.

Different measurements can be produced according to the costumer requirements.

ALBAROLL WITH AUTOMATIC INSPECTION AND ALIGNMENT

MINIROLL INSPECTOR

Roll to roll fabric winding machine with:

- Encoder driven counter and pre-selection of measures.

- With inspection table.

- Electronic speed variator driven by potentiometer from 0 to 34 mtrs.

- Start and stop push button.

- Direction of rotation selector (forward-backward).

- Roll capacity: In cradle (450 mm diameter) and in winding (260 mm wide).

- Fabric capacity 1,600 mm wide.

- Can be manufactured in different lengths upon request.

MATERIALS TO BE PROCESSED:

- Mattress fabrics.

- PVC/PU sheets.

- Terry.

- Nappas.

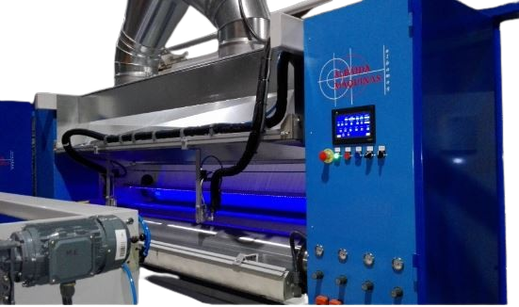

BASIC TECHNICAL CHARACTERISTICS:

Useful working width: 2200mm.

Roller engraved by dots: Application 9-12 g/m2.

Maximum diameter of inlet film reels: 500mm.

Maximum mechanical speed: 25mts/min.

Electrical connection: 400 VAC 50Hz.

Pneumatic connection: 8 Bar.

Smoke and vapour extraction connection: 800 Ø.

DESCRIPTION OF SUPPLY:

Film unwinder, service platform, opening roller, PUR/LAMINATOR coating unit, cable safety stops, fume extraction hood, material feeding gantry, laminating calender, rewinding and unwinding station for boot carts, screen with ultraviolet LED light for glue failure detection, oil thermoregulator, SELLA brand and glue equipment.

LAMINATOR